PRODUCTS

ASP5050 Type vertical chemical process pump (OH3)

Product introduction

ASP5050 series OH3 vertical pipeline pump series vertical, radial profile, single - stage, single - suction, pipe - type installation, cantilever structure. According to the requirements of API 610, the centrifugal pump for petroleum, heavy chemical and natural gas industry, the API 610, 8 and 9 are also met.

The sealing system is designed completely according to the API682 second version of the centrifugal pump and rotary pump shaft sealing system, which can be equipped with various forms of sealing and flushing cooling scheme.

Range of application

Refinery, petrochemical plant, general industrial process

Water and water treatment, seawater desalination

Coal chemical and cryogenic engineering

Pipeline pressure

Model significance

Structural characteristics

5.1 Flange: the inlet and outlet flange pressure level is the same, the nominal diameter is the same, the inlet and exit direction is side. Flange implementation standard can be selected according to customer requirements, GB, HG, ASME and other standards.

5.2 Pump cover: the pump cover is equipped with an insulated clamping sleeve and an exhaust plug design. The design of the insulating jacket can deliver the medium with special requirements for the temperature. The exhaust plug is used for pumping the pump body and the pipe emptying.

5.3 Sealed cavity: it meets the API 682 standard, large space size, can be equipped with multiple sealing type mechanical seal, and equipped with sealed cooling, flushing system.

5.4 Impeller: single stage, single suction, closed impeller.

5.5 Pump body: the diameter of 80mm is designed with double volute. The effective balance of the radial force reduces the vibration of the pump, so as to ensure the stability of the pump, and improve the service life of the sealing and bearing.

5.6 Low NPSHr: advanced optimization hydraulic model, reduce pump NPSHr, so as to reduce pump installation height requirement, thus reduce pump installation cost.

5.7 Rotation direction: from the motor end, the rotation direction is clockwise.

5.8 Reduce the cost of investment: vertical installation type, reduce the floor area, thereby saving the cost of base investment.

5.9 Independent bearing box: the motor and pump have a bearing frame, which can be used in higher temperatures and more important occasions than the coaxial pipe pumps.

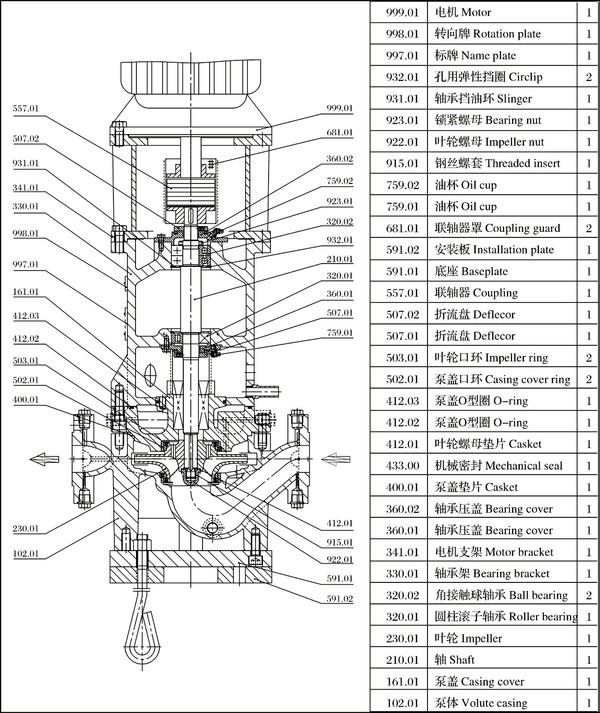

Sectional Drawing

Range Coverage Chart