PRODUCTS

ASP5320 Heavy-duty oil chemical process pump(BB2)

Product introduction

ASP5320 series heavy-duty petroleum chemical process pumps are horizontal, radial, single, two or three, center and double support layout. According to API 610, the standard of oil, heavy chemical and natural gas industry centrifugal pump is designed, and the design requirements of the eighth and ninth edition are met.

Sealing system completely according to API682 second edition of the centrifugal pump and the rotary pump shaft seal system design, with various forms of sealing and flushing cooling scheme, suitable for all kinds of complicated conditions, wide use.

Range of application

Widely used in petroleum refining, petrochemical industry, coal chemical industry, oil transportation, gas processing, offshore drilling equipment and other industrial processes, can transport all kinds of clean or with particles of neutral or has a strong corrosive medium.

The typical application in modern oil refinery transportation of crude oil and high temperature tower pumps and the need for continuous operation, can also be used as a large synthetic ammonia device for the poor liquid pump and the rich liquid pump.

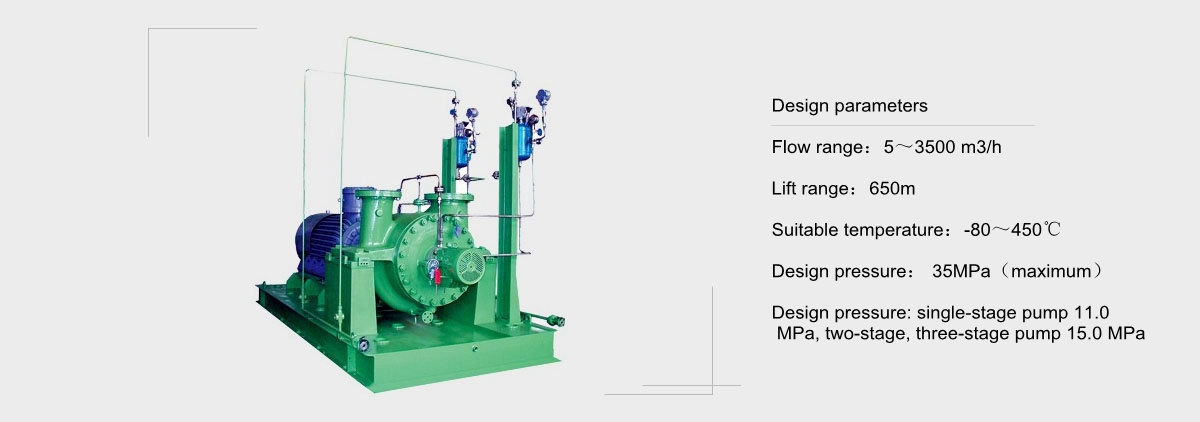

Design parameters

Flow range:5~3500 m3/h

Lift range:650m

Suitable temperature:-80~450℃

Design pressure: 35MPa(maximum)

Design pressure: single-stage pump 11.0 MPa, two-stage, three-stage pump 15.0 MPa

Model specification

ASP5320-480-400×2

ASP:Anhui sanlian pump industry co. LTD.

5320:Product code

480: Design point flow

400: Design pumping Lift

2: Impeller series (unmarked single class)

Product structure characteristics

1、Flange: ANSI B16.5 300 # RF flanges pressing API610 to face the back of flanges, sealing with a jagged cochlear groove;

2、Foot: special thickening design to ensure that the minimum deformation only occurs when a double API nozzle is subjected to the load.

3、Double volute design: minimum radial force to improve the service life of mechanical seals and bearings;

4、Impeller: double suction, staggered arrangement, guaranteed pump low pulse and low NPSHr, fixed, precision casting;

5、API610 taper shaft design: easy to remove coupling;

6、Bearing configuration diversity: bearing USES ball/ball, ball/sliding bearing, sliding/thrust plate bearing, ball bearing lubrication oil bath, sliding bearing is forced lubrication of thin oil;

7、Mechanical seal: the sealed cavity is in accordance with the API 682 standard, and can be sealed according to the working condition, without pressure double seal and double sealing.

8、With double side of the pump cover symmetrical pump body design, can achieve the same warm pump design, optional clockwise or counterclockwise turn, perfect maintenance space, can contact with all parts of maintenance, complete line of residual fluid design;

9、A variety of import and export location configurations: the standard is equipped with the top of the top and can also be imported or exported on either side of the pump, or on the same side.

10、Bearing box: 360 ° circumferential fixed way to reduce the vibration of the bearing housing, high efficiency cooling fan is most standard configuration, jilt lubrication way provide lubrication effect, prevent the lubricating oil "coke", also can choose pure oil mist or oil lubrication;

11、Sealing cavity: it meets the API 682 standard, the space size is large, it can be equipped with double end surface mechanical seal, easy to disassemble;

12、The performance of NPSH is optimized: double suction impeller is used, and the suction of impeller is good;

13、Integral type wear ring: reduce the risk of failure due to the replacement of wear parts, and special design can be carried out if needed.

14、Auxiliary interface is integral flange connection: no welding, no support, other forms of connection can be selected;

Optional material configuration

S-5、S-6、C-6、A-7-1、A-8-1、A-8-2

Note: different materials can be used according to the actual condition

Sectional Drawing

Range Coverage Chart