PRODUCTS

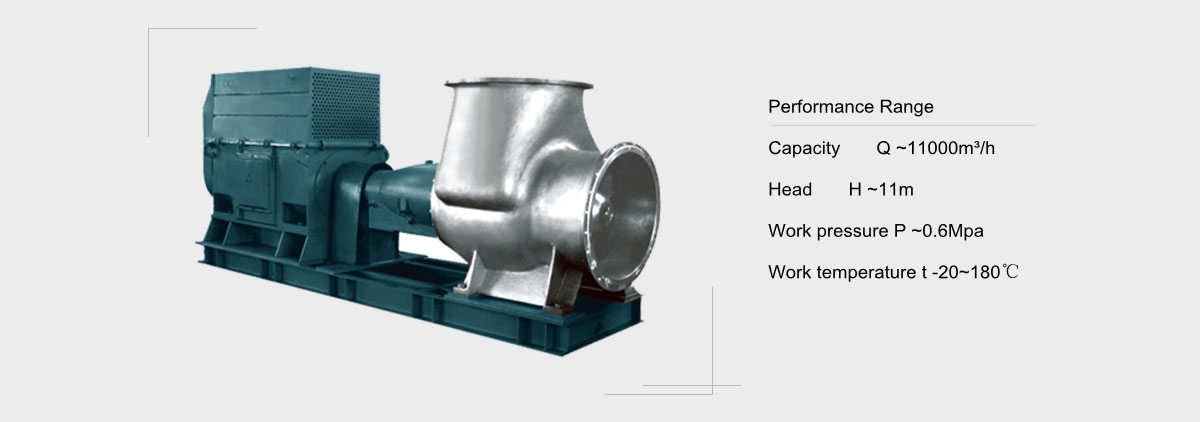

ASP5610 Series Chemical Axial Flow Pump

Description

Foot-mounted is applied on the pump casing and the pump is designed according to GB13008《Technical specifications for mixed and axial flow pumps》

ASP5610 series chemical axial flow pump includes horizontal、radial、cantilever type.

The pump is safe and reliable with steady operation and easy maintenance.

The pump is steadyhydraulic performance,high efficiency,and has large range of application.It is high efficiency and energy saving product.

Sealing can be packing seal and double mechanical seal,driving method can be directly-connected or belt drive,

Rotation direction:When getting from top and discharging from end,the pump rotates anticlockwise from the drive end.(Standard structure)

When getting from end and discharging from top,the pump rotates clockwise.(When user requests,the impeller nut is front seal head.)

Application Area

Transmit liquid that is nomal temperature,liquid that is neutral or corrosive;liquid that is clean or includes solid particles.Especially applicable to circulation system that is for salt&alkali making.

● Irrigation and drainage equipment

● Sugar industry

● Paper making and paper pulp industry

● Chemical industry and petrochemical industry

● Salt making and alkali making industry

Performance Range

Capacity Q ~11000m³/h

Head H ~11m

Work pressure P ~0.6Mpa

Work temperature t -20~180℃

Structural Characteristics

Inlet&outlet pipe have the same norminal diameter.

Inlet&outlet direction of ASP5610-300,ASP5610-350,ASP5610-450,ASP5610-500,ASP5610-600 is coming from top and discharging from bottom,and other specifications are coming from bottm and dicharging from top.

Thin oil lubrication rolling bearing shall be used.

Impeller and hub are casted into one,as for ASP5610-300,ASP5610-350,ASP5610-700,ASP5610-800,ASP5610-900,the impeller casting angle can be confirmed according to site condition,and as for other specifications,there is only one impeller casting angle.

Packing seal and double mechnical seal can be used.

Shaft is protected to avoid contacting the medium,so the meterial of choosing for shaft can be very extensive.

Belt connection can be used on ASP5610-250,ASP5610-450,ASP5610-600,

Motor direct-connection can be used on ASP5610-300,ASP5610-350,ASP5610-700,ASP5610-800,ASP5610-900,and belt connection can be used on ASP5610-500 as well as motor direct-connection.

Material of Wet parts

1Cr18Ni9、1Cr18Ni12Mo2Ti、incoloy804、1Cr18Ni12Mo3Ti and other material can be used as wet parts.

Special material can be used.

Model significance

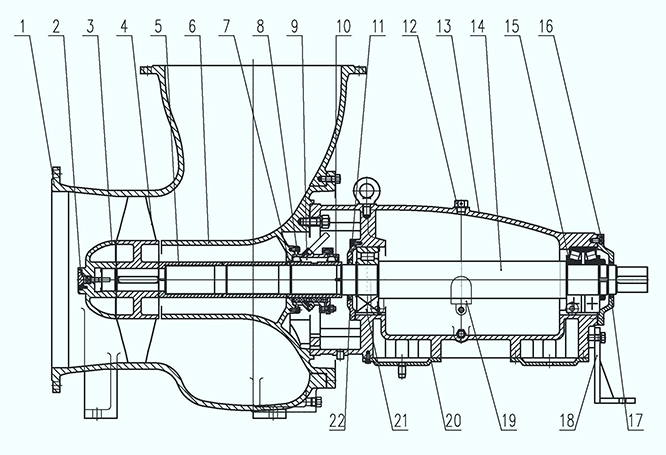

Sectional Drawing