PRODUCTS

IS、ISZ Single-stage

Description

IS、ISZ type pump is single stage single suction(axial suction)centrifugal pump.It can transport clear water or the liquids with physical or chemical properties similar to clear water,and the temperature can be no more than 80℃.This kind of pump is reliable,easy to install and maintain.

ISR、ISRZ type hot water pump can transport hot water whose temperature is less than 120℃.

Application Area

IS、ISR type pump is applied in industry and urban water supply,drainage,and also agricultural irrigation.

ISZ type pump is single stage single suction(axial suction)centrifugal pump is applied in industry and urban water supply,high-rise water supply,water supply for high-rise buildings,pressurization for fire pipe,hot and cold water circulation for air-conditioning,long distance water convey,production technique pressurization transportation,drainage for various equipment&boiler,etc.It can also be used for agricultural irrigation and the transportation of clear water and some other liquids with physical and chemical properties similar to clear water.

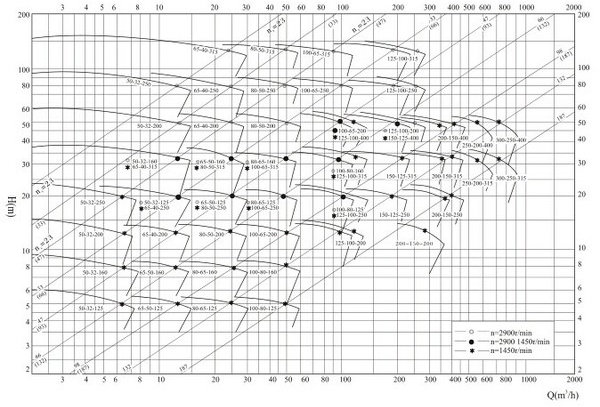

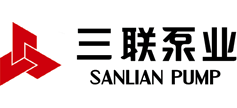

Performance Range

IS/ISR type series performance range

Inlet diameter:50-200mm(2"-8")

Capacity:6.3-400m3/h

Head:5-125m

Speed:2900r/min and 1450r/min

Matched power:0.55-110kW

Sealing has packing seal and mechanical seal.

ISZ type series performance range(According to design point)

Speed:2900r/min 1450r/min

Inlet diameter:50~300mm

Capacity:6.3~720m3/h

Head:5~125m

Ambient temperature:T≤40℃

Motor safety grade:IP54或IP44

Motor insulation class: B class or F class

Y2 or Y series motor is matched,mechanical seal

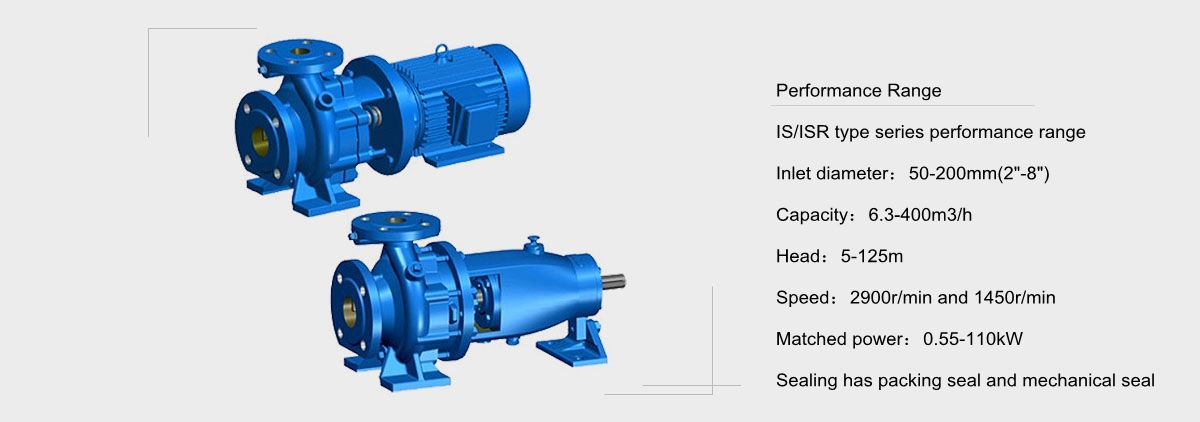

Code Identification

Structural Characteristics

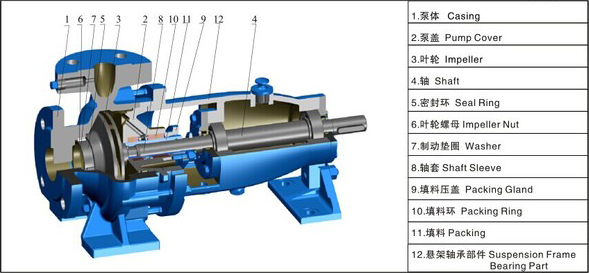

IS\ISR Structural Characteristics

The pump casing and pump cover of IS/ISR type pump are divided on the the back of impeller,which is usually called the back-open structural form.It is characterized by convenient repair on rotor without dismantling the pump casing,inlet and outlet pipeline.

The pump casing (the pump volute and pump cover)composes a pump’s working room.The impeller,bearing and roller bearing make up of a pump’s rotor.The suspension bearing part supports the pump’s rotor,and the roller bearing bears a pump’s radial force and residual axial force.

In order to balance a pump’s axial force,seal rings are always to be set at front-and-back cover plate of the impeller for most pumps,and balance holes are set at the impeller backboard.Because some pump’s axial forces are not strong,seal rings and balance holes are not designed for impeller’s back-cover plate.

The pump’s shaft seal is made up of packing gland 9,shaft sleeve 8 and packing 11,etc,or it adopts mechanical seal to prevent air from going in or avoid large quantity of water leak.

In order to avoid bearing abrasion,shaft sleeve protection is installed at the place where the shaft passes through the packing chamber.O-ring is installed between the shaft sleeve and the shaft so as to prevent air from coming in along the fitting surface or water leak.

The pump is driven through the connection of shaft coupling and electric motor.The pump rotates clockwise from the direction of the driver end.

Refer to diagram 5 and sheet 4 for the pump’s outline dimension;Refer to diagram 6 and sheet 5 for the inlet and outlet flange and its connection dimension.

ISR type hot water pump is made based on the IS type pump.There is a cooling chamber inside the pump cover,which makes use of normal-pressure cool water to cool down the packing part,so the temperature of medium transported can be as high as 120℃.

Furthermore,this type of pump can also be used to transport clear water of normal temperature.Meanwhile,it is unnecessary to feed water into the cooling chamber,and that one machine can have many functions can be realized.

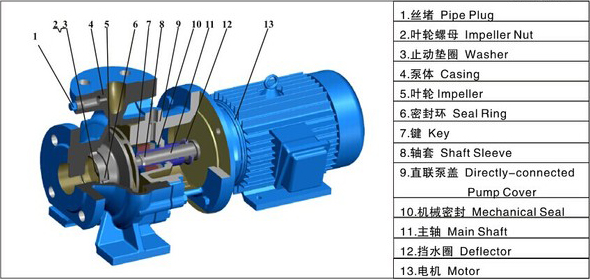

ISZ Structural Characteristics

The pump volute(the pump casing and pump cover)makes up of the pump’s working room.The impeller,the lengthened shaft etc are the rotational part of the pump.In order to balance the pump axial force,seal rings are set behind the back cover,and balance holes are also set on the impeller back cover.As the axial force is not powerful for some pump,there is no seal ring or balance hole set on the back of the impeller.

The pump sealing is made up of (10)mechanical seal,(8)shaft sleeve and so on to prevent air from entering and water from leaking.

In order to avoid shaft abrasion,the shaft sleeve protection is mounted where the shaft passes through the mechanical seal.O-ring is mounted between shaft sleeve and shaft to prevent air from entering and water from leaking along the fit surface.

The pump is driven through the direct connection of directly-connected pump cover and the motor.The pump rotates clockwise from the direction of drive end.

Sectional Drawing

IS/ISR structure chart

ISZ structure chart

Range Coverage Chart