PRODUCTS

XBD-T Horizontal multi-stage fire pump

Product introduction:

The XBD - T horizontal multi-stage fire pump group is one of the new products that our company develops according to market demand. This product according to international standard ISO2858 being adopted, and the new issued GB6245-1998 "fire pump performance requirements and test methods of specification requirements, using the most advanced hydraulic model, introduced according to the characteristics of the horizontal multistage pump design and manufacture of special fire pump. The products have the advantages of high efficiency, good cavitation, low vibration, low noise and smooth operation, etc., which are widely used in various kinds of fire fighting and life (production) water supply for industrial and civil buildings. Used to transport the chemical and physical properties of similar Yu Qingshui liquid, the highest temperature of the liquid is not higher than 80 ℃.

Range of application

It is widely used in various kinds of fire fighting and life (production) water supply for industrial and civil buildings

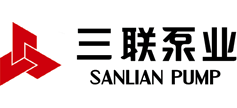

Model specification:

Inlet diameter: 50-150mm (2 "-8")

Flow volume: 5-45l/s

Yang cheng: 0.36-2.63 MPa

Turn speed: 1480r/min

Power: 4-180kw

Structural characteristics:

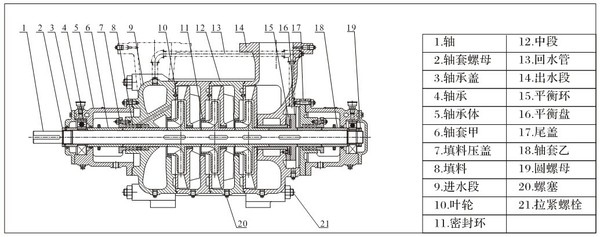

The xbd-t series horizontal multi-stage fire pump is a multi-stage centrifugal pump. The suction inlet of the horizontal multi-stage fire pump is in the horizontal direction of the water inlet, and the outlet is vertically upward in the outlet. The user can choose different series of pump according to the different lift requirements. The stator part of the pump consists of the water inlet section, middle section, the outlet section, the end cover and the bearing body. The rotor part of the pump consists of shaft, impeller, axle sleeve and balance plate. Pump inlet section, middle, outlet section of the joint surface between the paper gasket seal, in order to prevent water along the shaft into the bearing, the asbestos rope between the shaft sleeve used to seal, pump body on both ends of the shaft seals use packing seal, by adjusting the hold-down bolts, can cause liquid drip seeps shall prevail. The bearing USES rolling bearing, and the bearing is lubricated with calcium base butter. The pump is rotated clockwise from the inlet section.

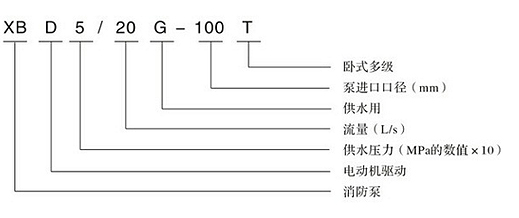

Model significance

Structure chart