PRODUCTS

XBD-I Fire Pump

Description

XBD-I series horizontal single stage fire pump is newly developed according to market needs.Its performance,technical conditions conform with international standard ISO2858 and requirements for national standard GB6245-2006《Performance requirements and test methods for fire pumps》.

Applications

It has been widely used in fire fighting and living water supply of industry the residence buildings.

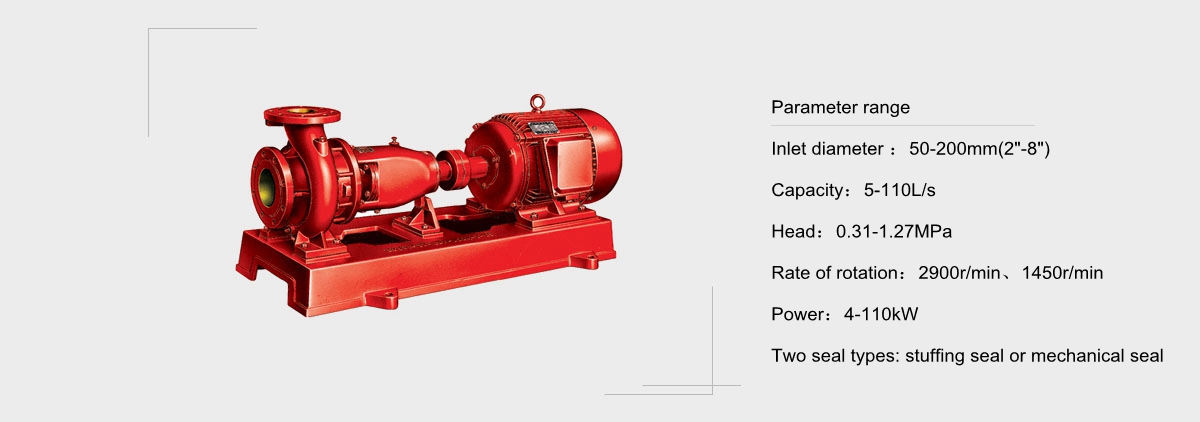

Parameter range

Inlet diameter :50-200mm(2"-8")

Capacity:5-110L/s

Head:0.31-1.27MPa

Rate of rotation:2900r/min、1450r/min

Power:4-110kW

Two seal types: stuffing seal or mechanical seal

Structural Characteristics

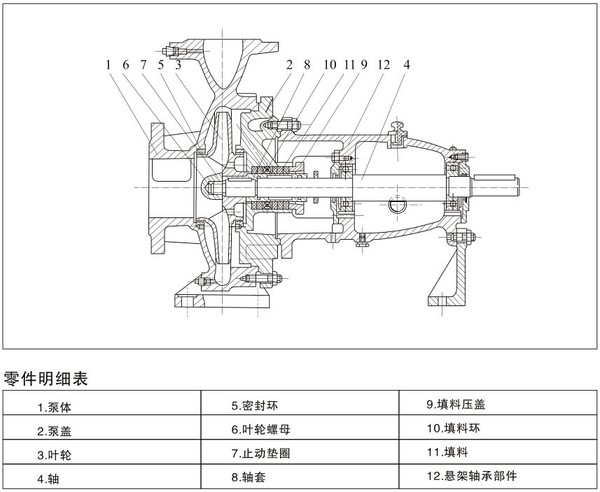

XBD-I series horizontal single stage fire pump set is mainly made up of 1.pump cover 2.impeller 3.shaft 4.seal ring 5.packing ring 10.Suspension bearing parts 12 .etc.

Pump casing and pump cover of XBD-I series horizontal single stage pump are split from back of impeller,namely,back-open structure.It is convenient to maintain,when maintaining,pump casing,suction pipe,discharge pipe shall not be dismantled,so rotor parts can be taken out for maintenance easily.

Pump casing(namely,pump body and pump cover) composes pump working room.Impeller,shaft and rolling bearing are rotors of pump.Suspension bearing parts support the rotor parts,and rolling bearing bears the radial force and residual axial force of pump.

To balance the axial force of pump,there are seal rings on the front shroud and back shroud of impeller,and there is balancing hole on the impeller back shroud.Some of the pumps do not have too much axial force,so there are no seal ring or balancing hole on the impeller back shroud.

Pump seal is made up of packing gland 9,shaft sleeve 8 and packing 11,or mechanical seal is applied to avoid air getting inside or too much water leakage.

There is a shaft sleeve through the packing cavity to avoid shaft abrasion.There is o-ring between shaft sleeve and shaft to avoid the air getting inside or water leakage.

Driving way of pump is connected through coupling and motor.Pump rotates clockwise from the direction of drive.

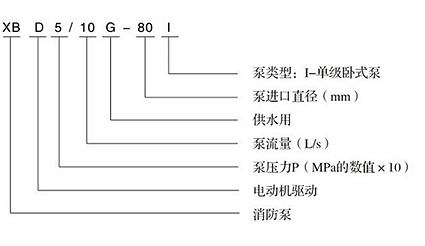

Model significance

Structure chart

- LAST:XBD-S Fire Pump

- NEXT:XBD-G Fire Pump