PRODUCTS

XBD-DL Fire Pump

Description

XBD- DL series fire pump set is vertical single suction multistage sectional type centrifugal pump,which is developed according to market needs.The product applies the most advanced hydraulic model,combines with the characteristics of vertical multistage pump, according to International standard ISO2858 and newly-issued national standard GB6245-2006《Performance requirements and test methods for fire pumps》.The product is high efficient and energy-saving,reliable performance,easy to install and use.It transports water and liquid with physical and chemical property similar to clean water.Temperature of liquid can not exceed 80℃ at most.

Application Area

It has been widely used in fire fighting and living water supply of industry the residence buildings.

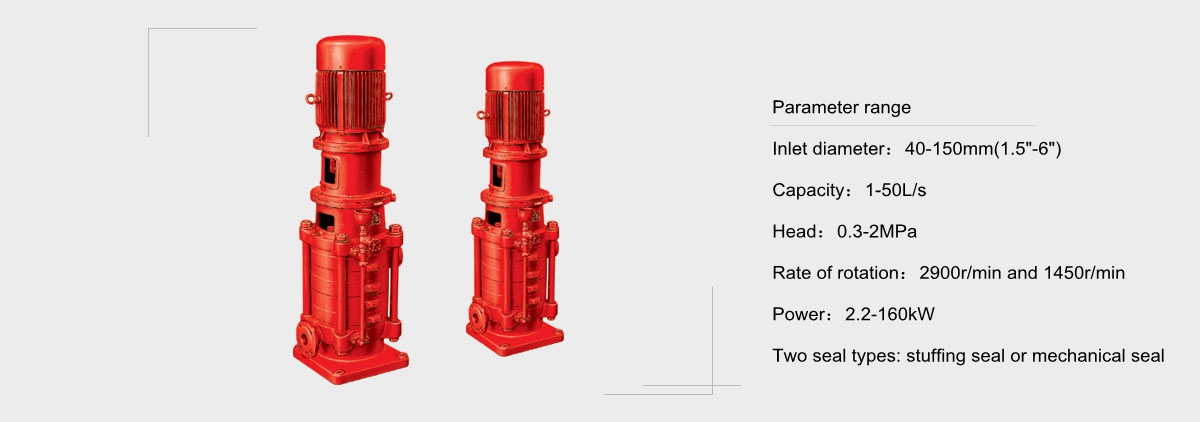

Parameter range

Inlet diameter:40-150mm(1.5"-6")

Capacity:1-50L/s

Head:0.3-2MPa

Rate of rotation:2900r/min and 1450r/min

Power:2.2-160kW

Two seal types: stuffing seal or mechanical seal

Structural Characteristics

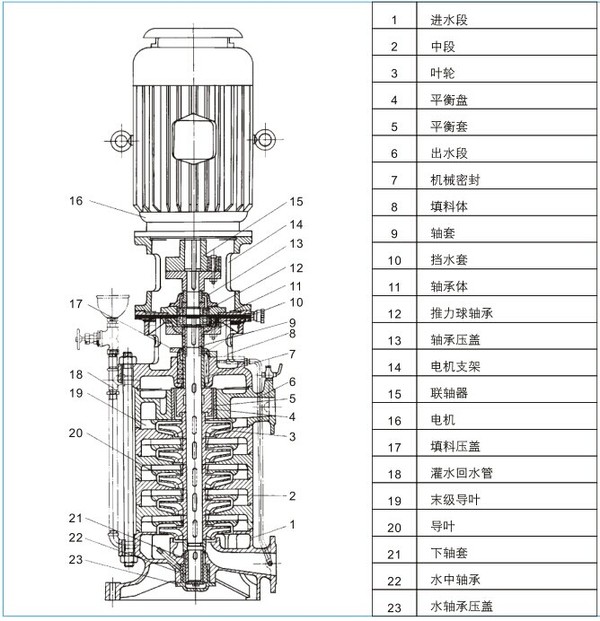

XBD- DL type fire pump is vertical multistage sectional structure.Its suction is placed at the inlet section,and its discharge is placed at outlet section.And they are both horizontally placed.Head can be needed by increasing or reducing pump stage.According to installation using requirements,outlet section can be rotated 4 directions,namely,0°、90°、180°、270°,to adjust the installation position of discharge.

XBD- DL type fire pump mainly contains:inlet section,middles section,outlet section,packing support,impeller,guide vane,the final stage guide vane,the final stage guide vane,shaft,bearing,shaft sleeve,seal ring,balancing sleeve,motor support,etc.(See structural diagram)

Inlet section,middle section,outlet section,guide vane,the final stage guide vane are all made of cast iron,and are whole part of pump working room.

Impeller is cast copper.Liquid gets into unilaterally along shaft,due to axial force,the balancing disc shall bear most of the axial force,while little axial force is born by radial-thrust ball bearing on the shaft upper end.

Shaft is high quality stainless steel with impeller,balancing disc,bearing and shaft sleeve in the middle.Key,nut and lined nut are fastened on the shaft ,composing rotor parts.Lower shaft sleeve is installed on one end of shaft,matching with the bearing made of fluoroplastic.Radial-thrust ball bearing is installed on the other end to support the rotor parts with coupling parts install on it to connect with motor directly.

Seal rings are installed on the inlet section,middle section separately.Two kinds of seal rings are used cooperatively in order to decrease the high pressure water leak back to inlet section.These two seal ring are wearing parts,they can be replaced after abrasion.

Balancing disc and balancing sleeve compose the balancing device of pump.They are wearing parts,they can be replaced after abrasion.

Shaft sleeve is high quality carbon steel,located at the packing room to protect shaft.In order to avoid the mass loss of liquid,not only can soft packing be used on the shaft seal,but also can be exchanged with mechanical seal.When soft packing seal is used,shaft sleeve is wearing part that can be replaced.

When mechanical seal is used as shaft seal,the pressure water in the balancing room can be used to lubricate and cool.Leakage water is led into water pipe by rubber hose.

When mechanical seal is used as shaft seal,3/8”hose connection on the outlet section drainage the leaked water from packing body to the pit through hosepipe to make the surrounding of pump clean.

Calcium-based iodized oil lubrication is used on the pump upper bearing.

Pump rotates anticlockwise when looking down from the direction of motor end.

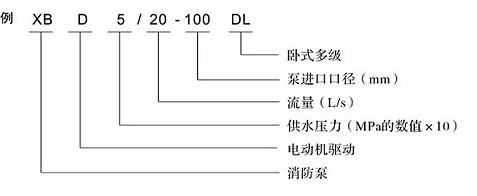

Model significance:

Structure chart

- LAST:XBD-G Fire Pump

- NEXT: