PRODUCTS

QJ(R) Submersible well pump

Product introduction

Type QJ (R) Wells with submersible electric pump is designed according to the national standard of energy saving products, the type of pump by the QJ (R) submersible pump and YQS submersible motor of underwater integrated work, has a compact structure, small volume, low noise, no secondary pollution, installation, use convenient maintenance, safe and reliable operation, high efficiency and energy saving, no need to build the pump room, etc. Vertical and horizontal installation; It can also be used in open water and used as ground pump, which has advantages such as small footprint, no pollution and leakage and easy installation. It is the ideal substitute for centrifugal pump, such as traditional ISG and DL.

Range of application

It is mainly used to extract groundwater from deep Wells, and is widely used in water supply and drainage of farmland irrigation, water supply and drainage of cities, industrial and mining enterprises, human and animal water and high-rise buildings in the plateau and mountainous areas. It can be used for water supply and other places.

Design parameters:

1. Power supply for three-phase alternating current of 50Hz and 380V.

2, water temperature shall not be higher than 20 ℃.

3. The content of solids in water (by weight) is not greater than 0.01%.

4. The PH value of water is 6.5 to 8.5.

5. Chlorine ion content in water is not greater than 400mg/L.

6. Submersible electric pump submerge depth not more than 70m.

The above conditions are the basic conditions of use. If the conditions of use exceed the above range, special production can be made to ensure the normal operation of the pump.

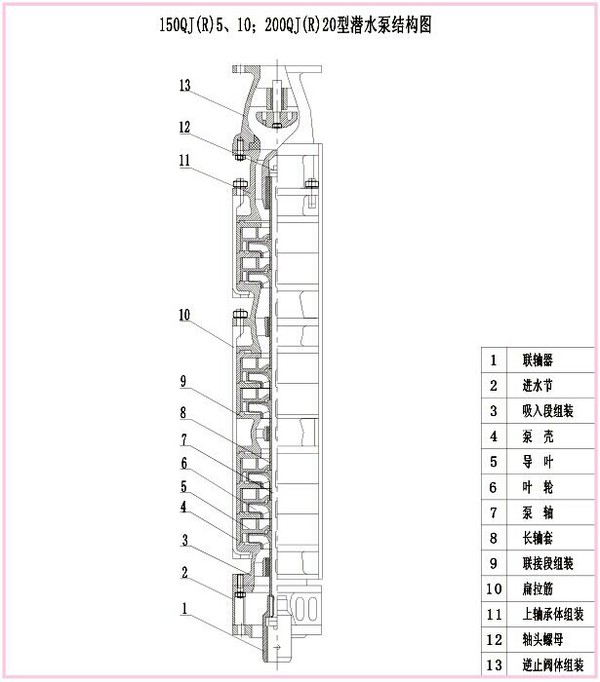

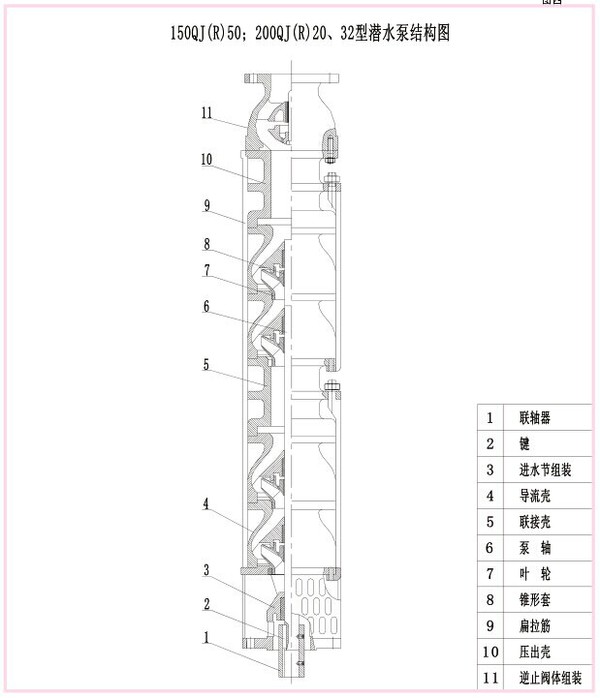

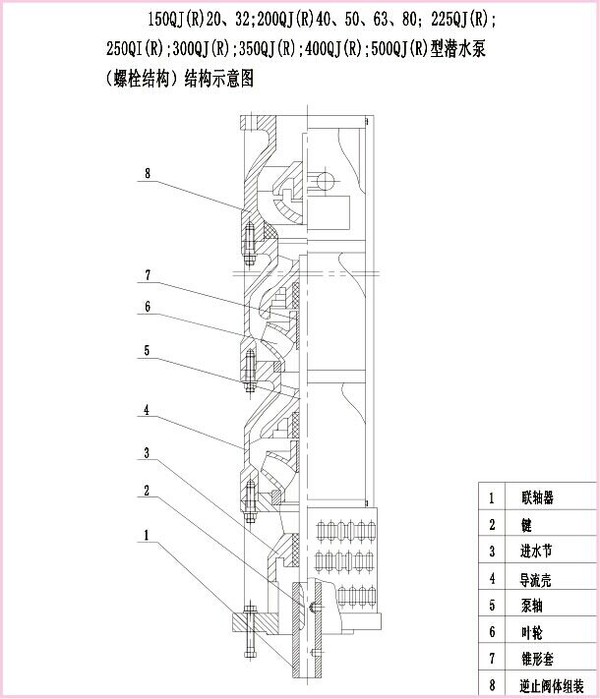

Structural characteristics

The pump is centrifugal or mixed. Water lubricated bearing; The coupling of the motor is connected with the coupling rigidity. The pump impeller is driven by the motor to generate centrifugal force, so that the liquid energy is increased and the flow of the pump shell is carried out. In the upper end of the pump, the reverse valve body shall be provided to prevent the water damage in the water pipe when the pump stops. The valve has a drain hole, and the water in the pipe can be released slowly to prevent the winter crack pipe. (note: the low lift submersible pump does not set the reverse valve body)

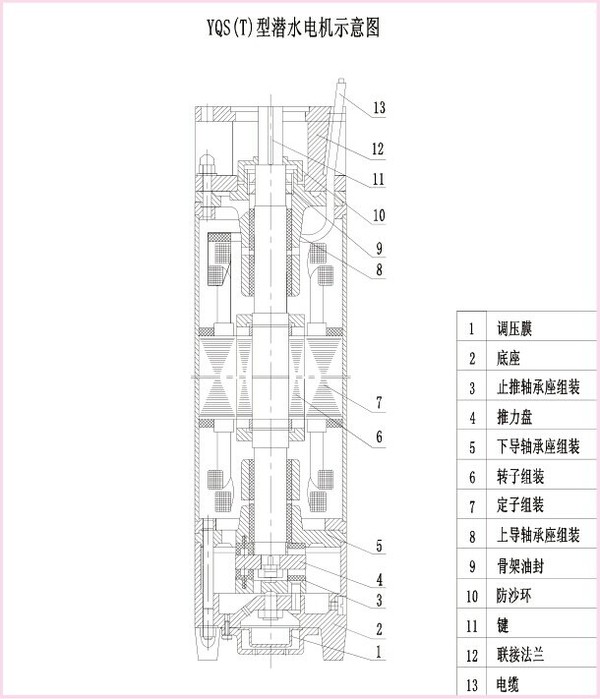

2. The motor is sealed and water-filled structure. The motor stator windings are used to insulate polyethylene insulated nylon sheath. The bearings and thrust bearings are lubricated by water. The motor is filled with water to cool the motor and lubricate the bearings. The bottom of the motor is fitted with a pressure membrane (made of rubber) to adjust the differential pressure of water in the body that is caused by the temperature rise of the motor. The upper shaft of the motor is equipped with a sand control mechanism to prevent sediment from entering the body.

3. Pipe part: it is used to connect the electric pump to lift it into the well, and the water will be sent to the ground. It is mainly composed of short pipes, pipes, elbows and splints. The short water pipe is the over-part of the transmission line and the electric pump. The bend is installed at the wellhead to change the direction of the flow. The plywood is the hoisting and fixed output line during the installation of the electric pump.

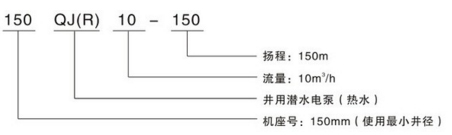

Model significance

Sectional Drawing

- LAST:YQ/ZQ/BQ Series mine submersible pump

- NEXT: