PRODUCTS

ASP5330 Heavy-duty oil chemical process pump (BB3)

Product introduction

ASP5330 and ASP5331 series BB3 heavy duty oil chemical process pump shafts are divided into sections, multi-level and double volute, and the center installation and double support arrangement structure. According to API 610, the standard design of oil, heavy chemical and natural gas industrial centrifugal pump. ASP5331 specially designed for high temperature, high pressure and other extreme conditions design of double hull axial profile, horizontal multi-stage centrifugal pump.

Range of application

Mainly used in oil, petrochemical industry, chemical industry, coal chemical industry, pipeline, water desalination, power plants, etc., can also be used in the coal chemical industry in the ash pump, poor methanol pump, chemical industry of high pressure hydraulic energy recovery turbine, chemical fertilizer, ammonia plant of lean liquid pump and liquid pump, etc. The typical working conditions are used for boiler feed water of power plant, the steel mill is divided into the phosphorus, the oil field water injection and other high pressure occasions.

Model specification

ASP5330 (ASP5331)300-180×6

ASP5330 (ASP5331):Product series code (ASP5330 for single shell, ASP5331 for double housing)

300:Design point flow

180:Design point lift (single stage)

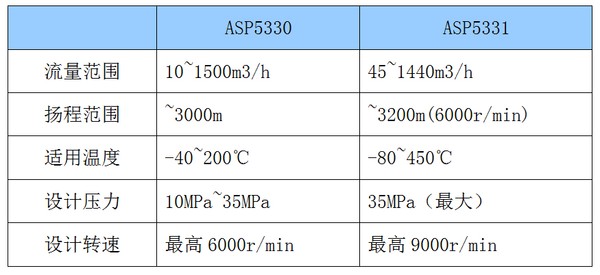

Design parameters

Structure characteristics

1、Impeller: heat installation, precision casting, dynamic balance, single fixed, can choose integral impeller;

2、Double volute design: minimum radial force to improve the service life of mechanical seals and bearings;

3、Large shell mounting hole: suitable for use of non-metal wear resistant parts without modification;

4、Optional interstage tap interface: one pump delivers multiple streams;

5、The integral stage bushing and guide plate: the tongue type fixed mode, the axial position of the axial dissection;

6、Optimization of NPSH performance: double suction impeller can be used, and the suction of impeller can be good;

7、Top bolt connection: no need to support heavy hydraulic torque wrenches;

8、Bearing configuration diversity: bearing USES ball/ball, ball/sliding bearing, sliding/thrust plate bearing, ball bearing lubrication oil bath, sliding bearing is forced lubrication of thin oil;

9、Bearing box: 360 ° circumferential fixed way to reduce the vibration of the bearing housing, high efficiency cooling fan is most standard configuration, jilt lubrication way provide lubrication effect, prevent the lubricating oil "coke", also can choose pure oil mist or oil lubrication;

10、Sealing cavity: it meets the API 682 standard, the space size is large, it can be equipped with double end surface mechanical seal, easy to disassemble;

11、Overall throttle bushing: for relief, dimensional change to balance axial force;

12、API610 taper shaft design: easy to remove coupling;

13、Large diameter shaft: the stepped shaft is easy to assemble, and the axial dimension meets the rotors, dynamics and power transmission requirements under the gap of wear, optimizing the design for hydraulic performance;

14、Replaceable wear ring: press fit and axial pin fixed, the whole impeller opening ring can be selected ;

15、Semi-intermediate liner: easy to check, remove and replace;

16、Axial split shell: simplified rotor balance, inspection and installation procedure, easy to check and modify the shell flow and retrofit spare rotor; The pipe and lower shell are cast into one body, which can not remove the pump inlet and outlet line during the maintenance of the rotor.

Optional material configuration

S-5、S-6、S-8、C-6、A-7-1、A-8-1、A-8-2、D-1

Note: users can choose different materials according to the actual working conditions

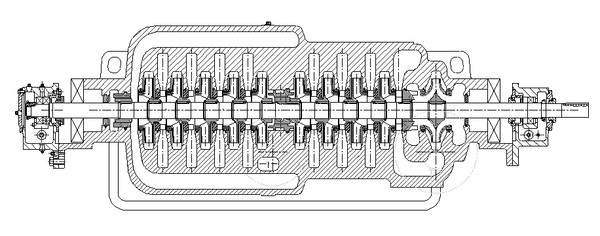

Sectional Drawing

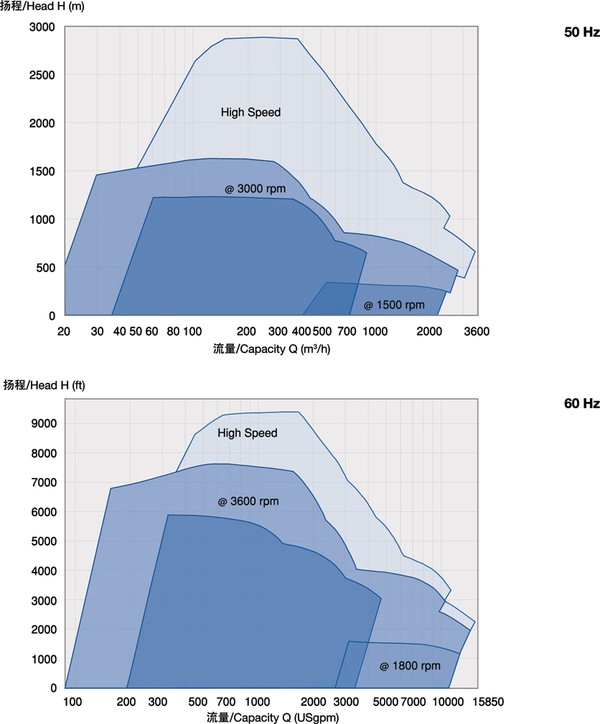

Range Coverage Chart