PRODUCTS

ASP5560 Series Pump(VS6)

Description

ASP5560 series pump is multistage、radial-sectional vertical barrel pump.It is designed and manufactured according to API610 version 10《Centrifugal pumps for petroleum petrochemical and natural gas industries》as well as version 8,9.The rolling bearing of the pump is thin oil lubrication,and submersible sliding bearing is multi-point supported structure,and supporting、cooling、installation maintenance have been considered and designed carefully with all kinds of auxiliary and monitoring system,which make the pump more reliable and much safer.

The pump has high using performance with various structures,and the best configuration can be chosen at different condition.

The first stage impeller and secondary impeller are designed separately,and the first impeller has high cavitation performance.Secondary impeller has high efficiency,and radial or space guide vane type delivery chamber shall be used,with no hydraulic radial force.

Sealing chamber confirms to the standard requirements of API1682 version 2《Shaft sealing system for centrifugal and rotary pumps》,and all kinds of seals can be used.

Application Area

Transmit liquid that is clean or a bit polluted or liquid that is low temperature or high temperature,neutral or corrosive.

● Refinery

● Petrochemical plant

● Power plant

● Low temperature engineering

● Pipeline pressure

● Offshore oil production platform

● Liquefied gas engineering

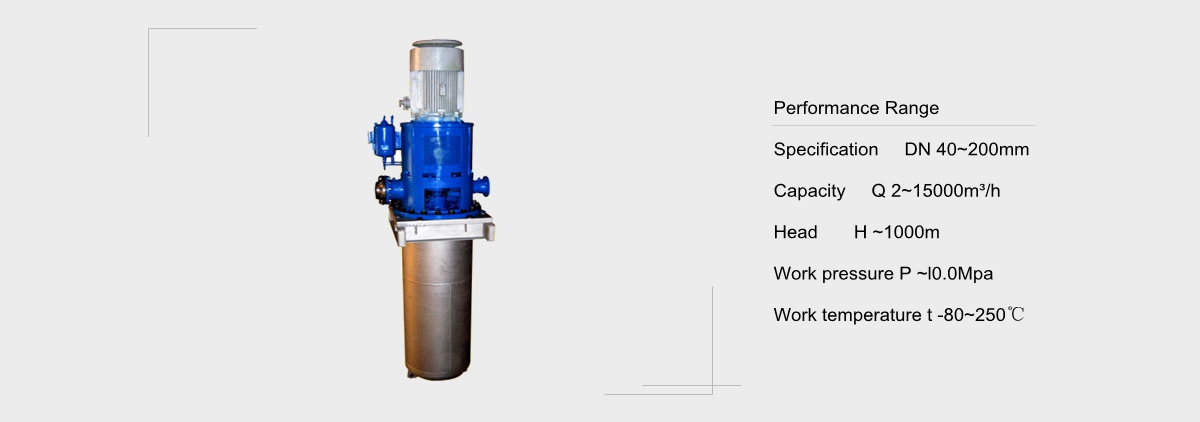

Performance Range

Specification DN 40~200mm

Capacity Q 2~15000m³/h

Head H ~1000m

Work pressure P ~l0.0Mpa

Work temperature t -80~250℃

Structural Characteristics

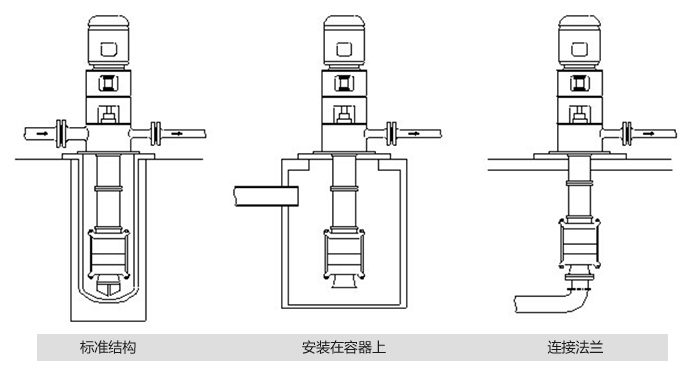

Vertical barrel pump is multistage,radial-sectional type.Type of impeller is single suction radial type with single casing.The first impeller is suction type.Axial force is born by radial-thrust ball bearing.When the differential pressure is getting higher,the balancing drum device shall balance the axial force.External pump casing only bears the inlet pressure,and the length of external pump casing and the installation depth of pump shall depend on the requirements of NPSH cavitation performance.

The position of suction pipe and discharge pipe is on the mounting flange with 180 Degree,and other way of arrangement shall also be acceptable.

The standard of flange is DIN,ANSI or GB.Connecting thread of auxiliary piping shall use G or Rc/R,and the motor operates by flexible coupling(jaw coupling).

The pump rotates anticlockwise from the direction of drive end.

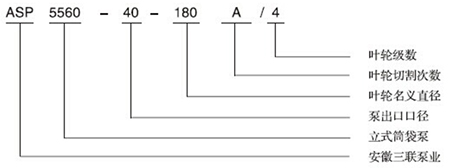

Model significance